History of Pigments: Tyrian Purple

How were garments dyed purple before synthetic pigments? And why was it worth more than gold?

Why does purple pigment from snails go for $2,700 USD per gram?

Most colors and inks these days are synthetically created, and are much cheaper and easier to create than traditional methods. But how were pigments created before we could synthetically create pigment from oil? This is a small history of the natural history of Tyrian Purple pigment made from snails’ intestines and what the current state of the pigment is.

History

Tyrian Purple, also known as Royal Purple, was used to dye the garments of royalty, and was first discovered in the Bronze age (around 14C BCE), and used extensively by the Romans. The color is a purpley-red shade that was often described as similar to the color of clotted blood (ew).

Made from a few types of sea snails, the dye was extremely time consuming to extract, hence its rarity and prestige.

In Phoenician mythology, the discovery of purple was credited to the pet dog of Tyros, the mistress of Tyre's patron god Melqart. One day, while walking along the beach the couple noticed that after biting on a washed up mollusc the dog's mouth was stained purple. Tyros asked for a garment made of the same colour and so began the famous dyeing industry. (World History)

How is it Made?

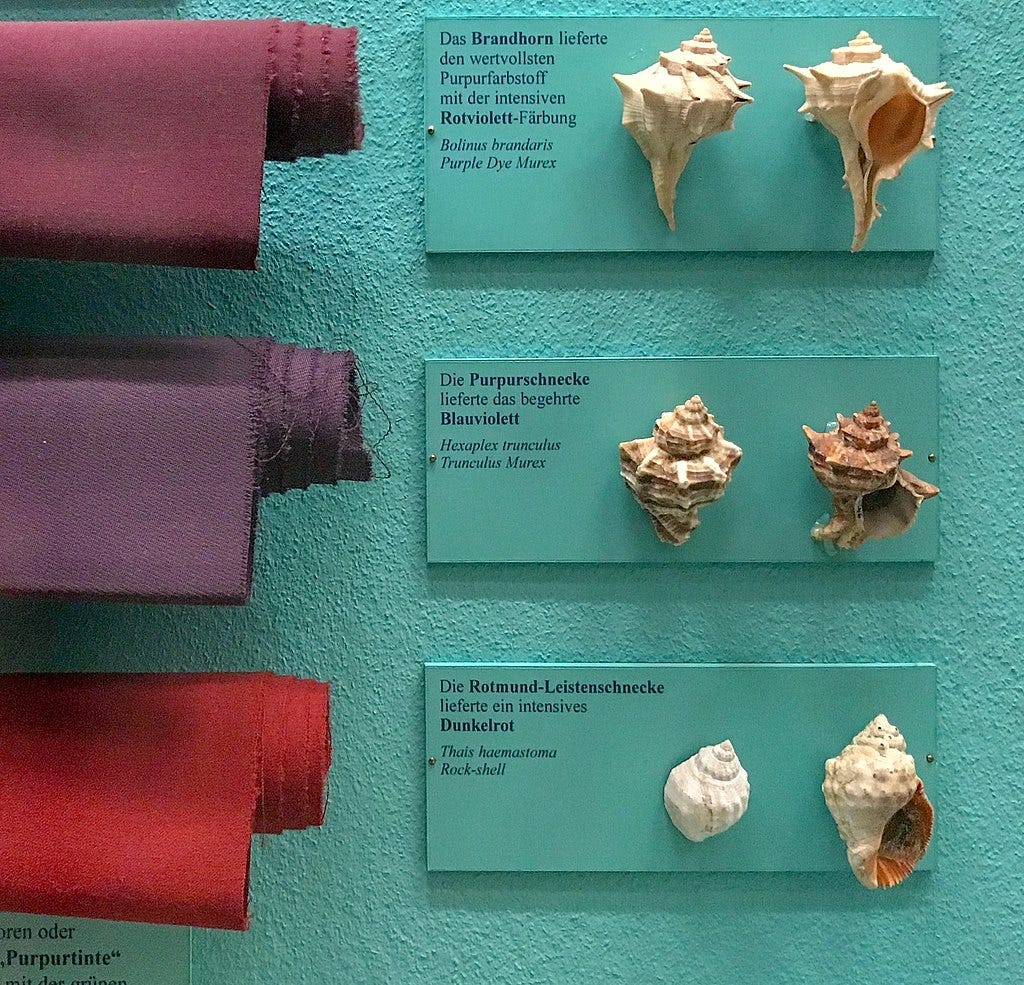

The dye is a fluid extracted from a few different species of snails, most commonly: Hexaplex trunculus, Purpura lapillus, and Bolinus brandaris. The snails were trapped and harvested for their dye glands. The dye produced is extremely long-wearing and resistant to fading, but only a tiny amount of pigment is able to be extracted from a single shellfish. This increased harvests and left apparently huge piles of shells left to bake in the sun. Approximately 10,000 snails yield only enough dye to colour a hankerchief.1

The dye comes from the snail’s hypobranchial gland. It seems this gland is likely repsonsible for the snail’s defense mechanisms and the extretions only turn coloured when exposed to the air. The method to extract the dye was record by Roman naturalist, Pliny the Elder, consisting of:

crushing the snails

leaving them to purify for 3 days in alkaline salt water

boiling them for over a week2

Although the shellfish glands can range in colour from pink to dark purple, so secret recipes for shellfish blends, extractions methods, and additional ingredients were well-kept secrets.

Some of the species of snails were harvested to extinction due to the demand for the dyes that were the backbone of certain Phoenician economies during this time. Eventually dye production ceased when the Ottoman Empire came to power, as green became the new purple.

It costs how much?

During the Roman empire, one pound of the dye was equal to a quantity of gold worth $19,000USD in today’s money3. Now, the dye is worth $2,700 a gram, a pound would be equal to just over $1.2 million dollars. Expensive!

Current Use

The dye is still being created and harvested. A few companies have figured out how to extract the dye from the snails, however, another hobbyist, Ghassen Nouira, has figured out his own methods for extracting the dye using traditional methods and turned it into a small traditional business. He has a Facebook page with examples of his dye and sells tiny bottles of the powered dyes. He had a hard time figuring out the method though: no public knowledge of it really remained other than the vague description by Pliny the Elder, and the corporations were tight-lipped about their methods.

“Actually, no-one could give me any advice because so few people were doing it, so I had to go it alone, learning the hard way,” Nouira explains. After two years of experimentation, he produced his first pigment powder. (Middle Eastern Eye)

The process takes over 45 minutes where the gland secretion darks from yellow to blue to purple.

Future Innovations

The harvest isn’t exactly sustainable. Nouira’s process focuses on wasting nothing:

“Nothing is wasted. My family eats all the snails after I have removed the glands. I can also bake the shells in large pottery furnaces, then grind them, which results in a very high-quality lime, that can be used as a building material, as a base for Purpurissum (purple paint pigment), makes an excellent fertiliser for acidic soils, and can even be reused instead of soda in dyeing processes,” he says. “And all this from a simple snail.” (Middle Eastern Eye)

However, not all companies can say the same. And the snails are highly sensitive to climate crisis and warming temperatures in the oceans.

As a result, a biotech start up, Conagen, is creating an animal-free alternative to traditional methods. They are developing Tyrian purple through fermentation.4

“Conagen is democratizing the exclusive use of a color once reserved for royalty --- now obtainable on a global scale,” said Casey Lippmeier, Ph.D., senior vice president of innovation. “Our fermentation and bioconversion technologies enable us to offer true-to-nature products. By leveraging Conagen’s bioengineering and commercial manufacturing capabilities, we’re unlocking Tyrian purple’s great potential as an accessible and sustainable dye. We expect Tyrian purple to inspire fresh ideas in multiple industries, making this rare and exciting color more marketable with planet-conscious consumers.”

Let me know if you enjoyed this topic! I’m very interested in the history of different natural pigments and hope you enjoy it as well!

https://www.worldhistory.org/Tyrian_Purple/

https://www.scienceinschool.org/article/2012/indigo/

https://www.worldhistory.org/Tyrian_Purple/

https://www.synbiobeta.com/read/conagen-starts-first-commercial-production-of-sustainable-tyrian-purple-for-textile-dye