Algae Ink promises high-contrast blacks, carbon sequestration, and light-fastness, but is it too good to be true?

There’s been a lot of talk in the design community over the last few years over algae ink–if you haven’t heard of it, you should have have, and if you aren’t using it, well why the f*ck not? Someone made it, so shouldn’t be be available for every project?

Unfortunately, until recently, algae ink was more of an artisan tool used for specific projects where the ink was developed specifically for that print run of the project in question, think the gorgeous dripping shots of Patagonia’s Boulder Guide book, pictured just below. I love that project, The Office of Ordinary Things really knocked it out of the park there, the photography is stunning and the design is beautiful. It put algae ink on the map. But somehow, the rest of us normies couldn’t request all our projects be done in algae ink. This isn’t their fault of course, but it just simply wasn’t available on the market. And, honestly, as I write this, it’s not like it’s suddenly accessible at every print house in North America or even Internationally–it’s just something we now might be able to find and request as a commercially viable product has been created by Living Ink. EXCITING!

The release comes with a lot of claims; that it can sequester carbon (instead of emit like most inks), and is therefore is the world’s first carbon-positive ink. That it can replace Carbon Black–the most common black used in printing and dyes, that it produces high-contrast, lightfast prints and more. In this issue, we’re gonna take a look at all of these claims, discuss print samples, and look back through the history of Algae Ink.

Algae Ink was first Popularized by Patagonia

This is where most of us will know Algae Ink from. Technically, Algae Ink was invented in 2015 and used in a few projects, but it was in 2019 when Patagonia in partnership with the design studio and Living Ink (also located in Colorado) produced this project and launched the Algae Ink hype across all of our screens. It was a bit of a slow roll after that: a few t-shirt projects, until in 2021 EcoEnclose started using Algae Ink for many of their mailers, but now the ink is available to be sourced by different printers. Living Ink lists EcoEnclose and D&K Printing as preferred printing partners, but Algae Ink can be used on any industrial printer without requiring extra cleanup or storage requirements.

Algae Ink looks pretty cool–we’ll talk about that later in the printing section, but you honestly couldn’t tell these are printed with algae ink instead of carbon black. The illustrations render very clearly.

How is it Made?

Algae Ink replaces the black pigment in traditional inks–this is usually comprised of something called carbon black. The algae is grown in California, usually for blue spirulina, a very blue pigment. The material left over after the extraction of the blue pigment is actually what Living Ink uses to make this black pigment. It’s a win-win for natural pigments, but in this issue we’ll just be talking about the black byproduct. This byproduct was traditionally just a waste product until Living Ink developed their process for turning it into ink.1

Living Ink has a few different formulations of their ink:

Algae Screen Printing Ink™ for Textiles / Fine Art Applications: A water-based screen-printing ink for textiles, wood etc.

Algae Offset Ink™ a soy-based offset ink suitable for use on coated or uncoated stock.

Algae Flexographic Ink™ a water-based ink suitable for corrugated and carton substrates.

Ink compositions are usually made up of the following quantities (although this changes based on formulation) so consider these just rough approximates:

45-60% varnish/carrier base (contains oils and resins, can be a mix of petroleum and plant-based)

15-20% pigment (usually fossil-fuel derived)

20% solvents (petroleum distillates)

3-10% additives like resins, varnish, driers, waxes, etc.2

What Algae Ink is doing is replacing 15-20% pigment from a petroleum pigment to a plant-based pigment. COOL! But let’s examine that feat a little closer!

What are the Environmental Benefits?

First, we have to talk about carbon black. It’s been mentioned a few times already in this issue already. So…

Carbon black is what comprises most black pigments, inks and dyes for all manner of things. It’s usually derived from coal tar or other petroleum tar variations. The International Agency for Research on Cancer (IARC) has evaluated that carbon black is a possible carcinogen to humans (Group 2B). Group 2B has restrictions for exposure (when the material is not usually interacted with directly by humans) or is based on incomplete human evidence while animal testing evidence of carcinogenic effects exists. California has also added carbon black to their requirements of ingredients that meet a Proposition 65 warning label (for cancer).

So this doesn’t mean any print material with black ink you handle is carcinogenic, mostly that the production and use of carbon blank during the creation/printing process might be hazardous. Regardless of its carcinogenic nature, to live in a better future less dependent on petroleum products, the coal tar ink has to go. Thanks to Algae Ink that time might be sooner than we think.

Is it really carbon negative?

Because algae have the capacity to sequester carbon, the algae farms being used to grow the raw ingredient for the ink are actually sequestering carbon from the air. Living Ink’s Algae Ink draws down and locks the carbon into the ink for over 100 years–longer than we need to buy us more time for the IPCC report. Woohoo.

Living Ink also claims:

Every 45 pounds of Algae Ink™ we produce keeps 22.5 pounds of petroleum (crude oil) from being used. That means that 22.5 pounds of oil can’t negatively impact our environment or our air. Additionally, because our ink is carbon negative, using a 45-pound bucket of Algae Ink™ can remove -59 kg of carbon dioxide or like planting four trees!

Honestly, nothing to fact-check here–it’s true algae is a great way to sequester carbon. In contrast, carbon black emits CO2 in its creation process.

Is it 100% petroleum free?

Honestly, I’m not sure. Living Ink has two different formulations for lithographic vs offset printing ink: one is water-based and one is soy-based. But neither of these mean that the full ink components are necessarily 100% petroleum-free or fossil fuel free.3 There’s a lot of different components that go into inks beyond the pigment and the carrier liquid: resins, varnish, driers, waxes, and more. Soy-based inks can meet that claim if it meets minimum requirements set out by the American Soybean Association which, depending on the printing method, is a minimum of 7-20% soybean oil. According to the ASA, black news ink contains 40% soy oil content.4 The rest of the needed carrier bulk can sometimes come in the form of traditional petroleum. There are a few reasons for this: cost as well as drying time for the ink. There are petroleum-free carriers, and Living Ink might very well be using them!5 But there’s no information publicly available. The Living Ink website is very careful to claim the pigment substitution (carbon black to algae) is petroleum-free, which is absolutely fantastic, but there are no such claims on the rest of the ink’s formulation, so we can’t know for sure.

But what does this mean? Honestly, it’s not that important. It’s easy to get bogged down in minutia like this and wanting to see something be 100% petroleum free, but zooming out, the truth is ink is <1% of your material use and we’re talking about reductions of petroleum likely at minimum 40-50% for the ink formula, and a pigment replacement of 100% petroleum-free to a pigment that isn’t carcinogenic. This is awesome. For me, it doesn’t matter if it contains a small amount of petroleum (if it even does) in the formulation because it’s a HUGE step forward in terms of ink composition; we’ve never seen such advancement in ink, even taking plant-based inks into account.

Can it be Recycled?

After our last issue on repulpability and foils, it’s only prudent to discuss if algae ink can be recycled well. There aren’t any specific studies for algae ink as of yet, however there are a plethora of plant-based ink recyclability studies and the answer is yes: leaps and bounds above petroleum-based inks. According to research done by the Western Michigan University, the deinking process is faster and more effective with plant-based inks than with petroleum-based ones.6

Printing Benefits

The benefits don’t stop with the environmental ones; Algae Ink comes with a whole host of awesome print features as well. I was lucky enough to receive these marketing materials and print samples from Hemlock Printers, one of the best printers in North America for sustainability according to Canopy's Blueline Ranking. It was only natural they would pick up and promote Algae Ink!

Color Tones

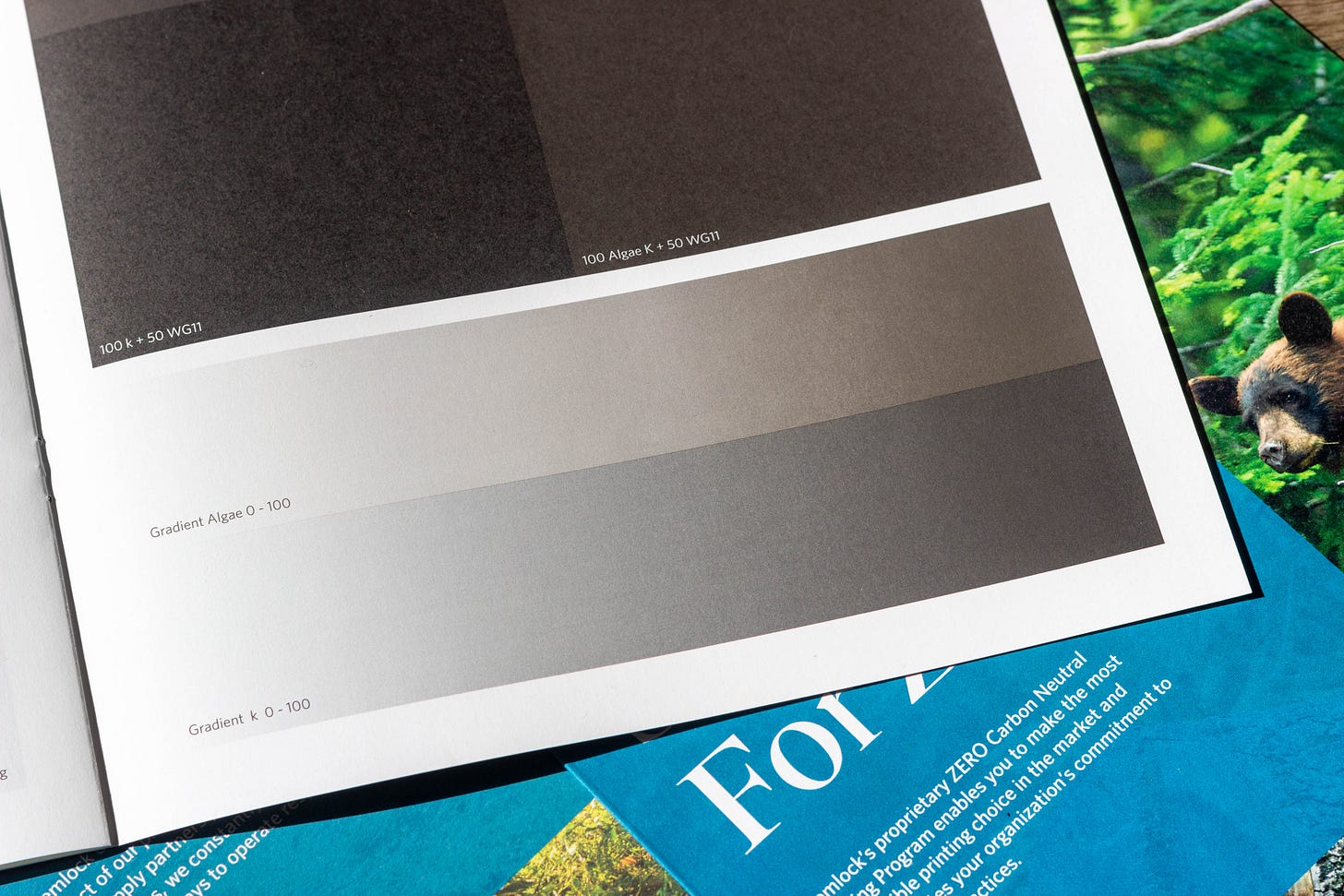

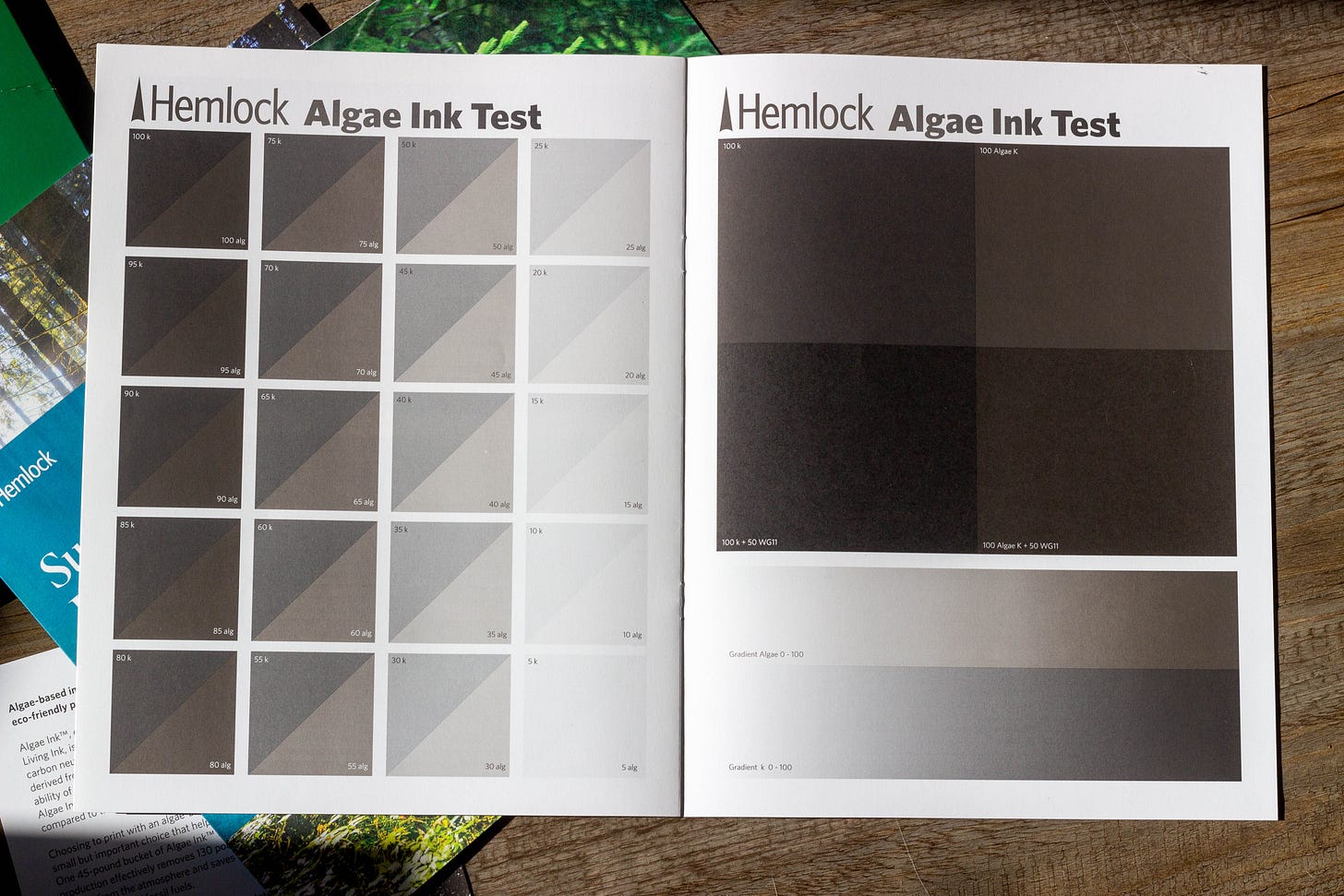

I tried to capture the samples as best as possible for the colour and differences. It’s truly only noticeable when they’re directly side-by-side, but you can see the algae ink is ever so slightly browner.

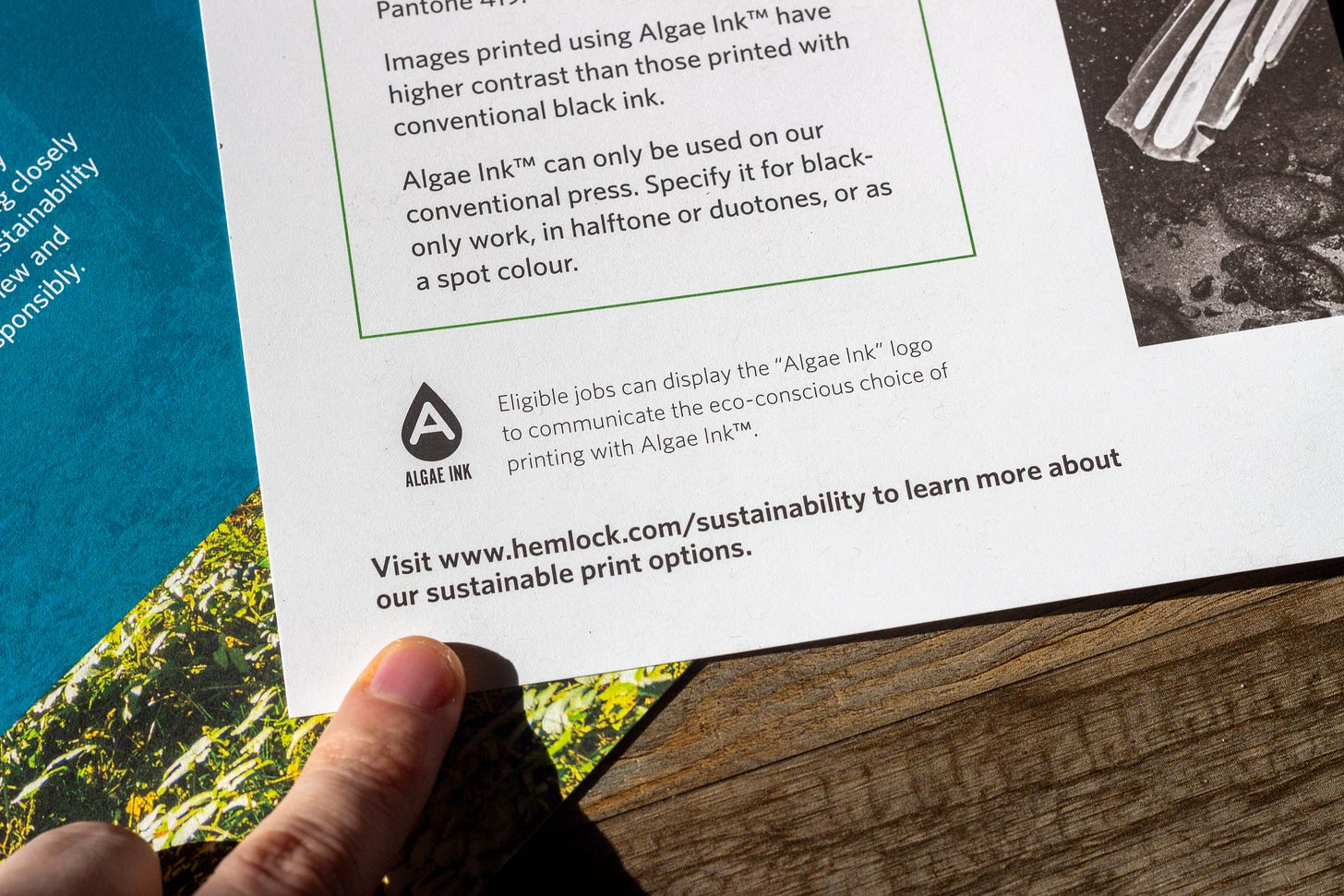

Hemlock notes that Algae Ink is a warm black similar to Pantone 419.

Hemlock notes that you should specify Algae Ink for black-only work in halftone or duotones, or as a spot colour.

Algae Ink also offers a higher contrast in photography than traditional Black printing. You can see the white details really pop on this half/half photo of a mountain face. In general, soy-based inks are also widely commended for higher vibrancy and some printers even report that they’re able to use less ink to cover the same distance/coverage on paper in comparison to petroleum-based inks.

Algae Ink also offers a higher contrast in photography than traditional Black printing. You can see the white details really pop on this half/half photo of a mountain face.

The ink is also lightfast, meaning it won’t fade over time from exposure to the sun. The algae pigment is extremely resilient to UV rays. I couldn’t find any indication if it was approved as “archival quality” due to its lightfast-ness but perhaps that study just hasn’t been done yet.

What about digital printing? Can I use it in my home office printer?

Unfortunately, not right now. Thesite says that the ink is not suitable for digital printing solutions right now. Hopefully in the future it will be, and then I can happily print algae ink on my sugarcane printer paper and feel very pleased with myself.

Does it come in any other colours besides black?

Not right now. The company is working on a range of other colours, but those are a ways off right now and only black is available.

Does it cost more?

Algae Ink can come at a 1-5% cost increase, depending on your print run. It sucks, but it’s not too unusual to pay more for a higher-quality product. If your clients are hesitant, talk to them about the huge messaging and marketing opportunity it represents.

Messaging; It’s a Great Conversation Starter

Speaking of marketing, using signage like this on printed works can be an amazing touch-point for communicating with the end consumer about the sustainable qualities of a printed piece. We always recommend our clients place certifications or transparent declarations of their sustainable commitments across their website and packaging to start the conversation. Algae Ink comes with that cute little logo to get the conversation started! These kinds of touchpoints are important and consumers are looking for this kind of transparent information more and more as greenwashing becomes more prevalent and nefarious.

Also as a final note, I want to thank Hemlock for sending me these samples. One of the best things you can do as a designer, especially a sustainable-focused one is to befriend printers and build relationships with reps. They’ll always keep you up to date on the latest advancements in sustainable printing!

Do you think you’ll end up using Algae Ink in a future project? Have you used it before?

If you thought this was cool, consider giving it a share to a friend!

Thanks for reading Green Graphic Design! Subscribe for free to receive new posts and support my work and get more detailed discussions like this one about niche green graphic design things.

https://livingink.co/faq-1

Based on a 1994 NSCEP document “Waste Reduction Evaluation of Soy Based Ink at a Sheet-Fed Offset Printer”.

A USA Patent discussing Soybean Oil / Vegetable Oil Offset Printing Ink Compositions https://pubag.nal.usda.gov/download/5875/PDF

https://soygrowers.com/soy-ink-seal/

A USA patent for petroleum-free carriers that speed up soy-based ink drying times. https://patents.google.com/patent/US5167704A/en?q=(soy+ink+composition)&oq=soy+ink+composition

https://scholarworks.wmich.edu/cgi/viewcontent.cgi?article=1210&context=dissertations