Are foils recyclable now?

A look into 2023 foil recyclability lab testing ft. a conversation with a foil representative.

The recyclability of foils has been a much debated topic over the years in the sustainable design community. A quick Google search reveals the, seemingly straightforward information, that yes, they are recyclable. The Foils and Specialty Effects Association proudly claims that cold foils are recyclable due to a new study conducted in 2021, and many other first-page Google results reference this study or similar as definitive proof that foils are recyclable.

So let’s take a look at that study. While not super easily available off of the FSEA’s website, we managed to find it online. We’ll now go through the study to determine its legitimacy, methodology, any conflicts of interest, and how the result measures up against other reports from recyclers themselves.

The Study [available here without emailing Jeff]

Conflict of Interest?

Right away, there are some immediate concerns about the credibility of the study.

‘Commissioned study by an industry group with a direct financial interest in the conclusion’ has a very different ring to it than ‘independent study in a peer-reviewed journal’, doesn’t it?

But let’s not go in with too many unfair questions like ‘how many studies did you commission to get these results?’ or ‘why isn’t this peer-reviewed?’.

Actually, those are very reasonable questions for any claims made about a scientifically rigorous study, because those are the basic requirements for what determines a real study—which this isn’t.

And it’s actually a somewhat fair defense. Questions around the recyclability of specific material and industry techniques are not the sort of thing that academics generally engage in, and for good reason. But before I get into that, I’ll just quickly summarize the findings of the ‘study’ (it’s really more of a lab experiment), ignore the conflict of interest and give it a fair evaluation.

The Findings

Basically they took a selection of paper/foil samples provided by the FSEA with varying degrees of high foil coverage (50%-100%), and treated them to the “simulated industrial conditions” of repulping/recycling..

Then they evaluated the structural integrity of the newly made paper out of that process (it was structurally normal), and tracked the aluminum’s final resting place (most of it dissolved into the acid used in the pulping process, and the rest was apparently readily filtered out).

It all seems… ok actually. The methods are explained, and a quick overview doesn’t reveal any glaring issues to a layperson (*wish upon a peer-review*), the data is openly presented. It delivered exactly what it promised to, showcasing that even with high coverage, foils didn’t seem to significantly disrupt the repulpability of the paper in a lab simulated recycling condition.

But don’t take my word for it! Here are the conclusions:

What are those red underlines doing there? Well, I think it’s only fair considering how much work they’re doing.

First of all, repulpability isn’t actually quite what we’re looking for. Repulping is an essential part of the recycling process, but overall our interest actually lies in the overall recyclability, which is a more complex context. So let’s get technical! Let’s try and evaluate the overall recyclability like real scientists! (“am I peer reviewer now mama?”).

For one thing, why are we so obsessed with what happens to the aluminum content? What about the other materials being used to apply the foil?

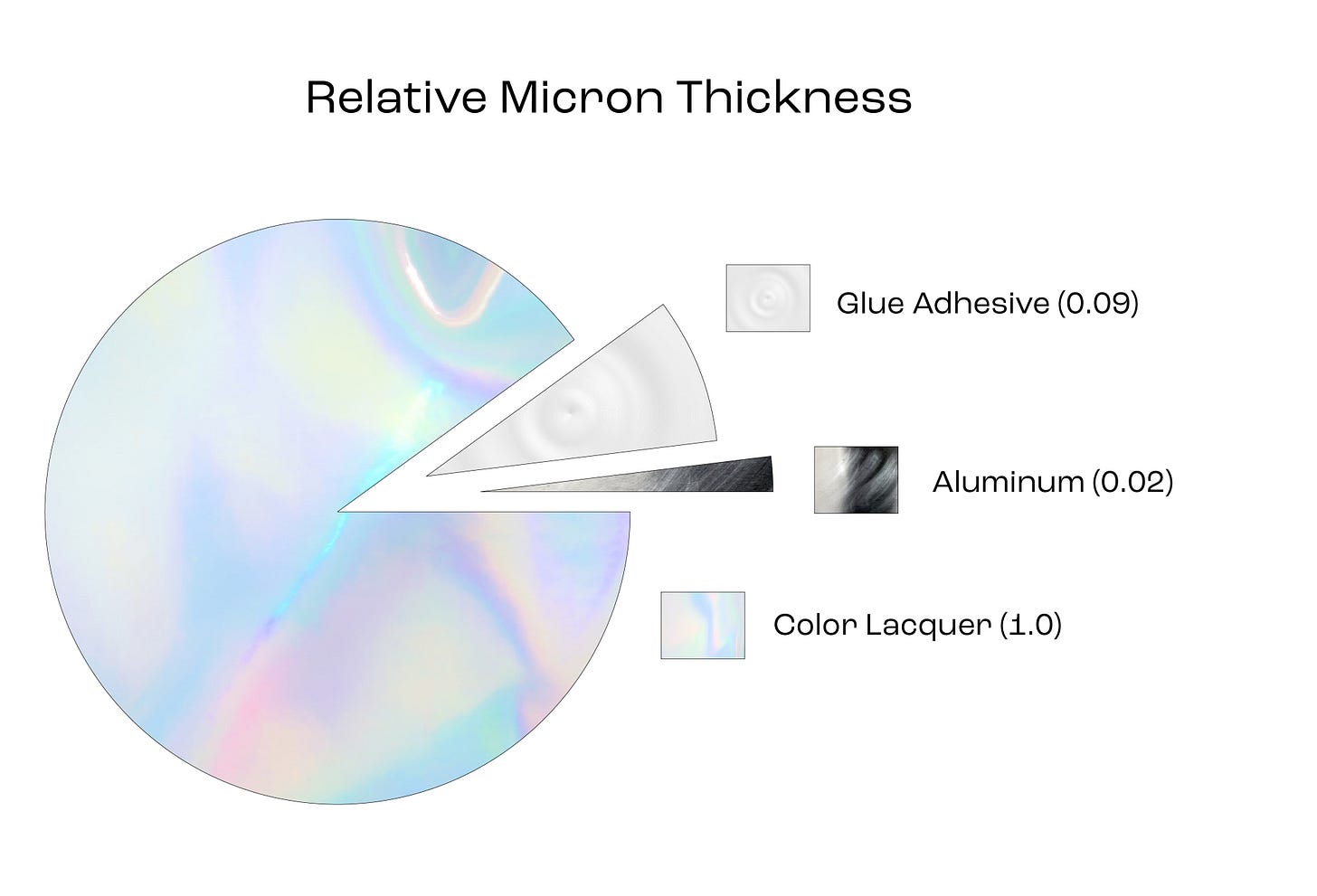

Oh. That’s why. Get my shovel! We’re burying the lede. Because a foil is more than just some isolated aluminum on paper, magically held together with fairy kisses. There’s an adhesive layer and a protective, coloured lacquer to contend with as well, there’s a lot more of them than any aluminum and they’re, well, they’re plastic. *ba dum tss*

Let’s Talk about “Stickies”

Now why are plastics, and particularly adhesives so problematic for paper recycling? Well, technically all contaminants need to be managed by paper recyclers, including the aluminum content. But paper recyclers are wise and handsome and have all sorts of methods to help remove all kinds of contaminants they have to in order to produce consistently useful and high quality recycled paper. These methods obviously incur costs for them, but considering the diverse and complex inflows they receive, there is no escaping these costs.

But adhesives and plastics in particular can become extremely tricky. To quote:

“Potentially tacky substances, called stickies, are now the most feared contaminants in recycled fibre pulps… Because of their tacky character, stickies deposit on wires, felts, rolls and other moving parts, especially on the paper machine.” (Bajpai, Pratima. In Recycling and Deinking of Recovered Paper, 1–19. Elsevier, 2014.) (Note: any effect of residues on the equipment used for the commissioned study were not discussed.) (One estimate I couldn’t find an original source for estimated $700 million in extra costs annually, so take that with a grain of salt.)

“Recyclable under Lab Conditions” Lab Study vs Peer-Reviewed

And this is why laboratory feasibility studies are usually bullshit. Just because it can be recycled, doesn’t mean it is economical or otherwise problematic. Most academics are aware of this, and the scientist who performed the study (whom I have nothing but respect for, I mean this sincerely he seems to be doing good work), is actually meticulous in his language not to overgeneralize the findings in the study. That’s what the industry group does instead.

This gets back to the earlier idea I mentioned, about how specific material and industry techniques are usually not specifically examined like this by academics. Because they know how to stay in their lane (most of the time).

The actual standard for evaluating the recyclability is to… ask the recyclers. Those people with diverse equipment, practical experience, and pragmatic understanding of what materials and practices impact their ability to do business.

What do Recyclers Have to Say?

Well, a 2021 survey by the American Forest and Paper Association (I know, I know, conflict city), titled “Design Guidance for Recyclability” had something else to say. The report interviewed recyclers across North America about the challenge of recycling different materials. The report found that “33% or more* of respondents rated [laminated, stamped, and metallised foils] as a challenge in mills.” The only exception to this was foils on kraft paper bags.

*No idea what the actual %’s are, such minutiae are not given to us.

Mic drop?

What about FoilCo?

Lately as I was chatting in the forums for the Print Design Summit, someone asked the recyclability of foils, and I said that until I’d seen some peer-reviewed or non-commissioned studies of recyclability, I’d have to default to the conservative decision that foils decrease the amount of recoverable fibres. A representative from FoilCo was in the chat and talked to me about the recyclability of their foils being unique from others.

A FoilCo representative replied to me, and this is what they had to say:

I replied and asked for them to send me that study on recyclability to my email, which I provided. This was close to a month ago and I have not heard from them. I assume they are not ever going to send me the study.

So the other place to turn was their website, perhaps the website has the study! It did not. Taking a look at FoilCo’s sustainability page was extremely disappointing and definitely not worth looking into. It is basically a series of FAQs with very short and non-informative answers. I’ve picked a few to discuss and highlight why they aren’t an effective or transparent way of displaying sustainability (and also why you can’t take marketing information provided by representatives at their word).

#1: Are Our Foils Compostable?

This one’s an awful answer for a few reasons.

The first being: it’s extremely misleading as a stand-alone claim about whether or not it’s industrial or home-compostable (or both), and seemingly implies home-compostability. It implies that all of their foils can be composted in any context under any condition and produce usable soil. This actually hasn’t been proven fully according to their rep though, as those tests are currently ongoing:

In my opinion, saying that they’re currently conducting lab composting tests is pretty different from claiming VERY boldly (and without a source) that their foils are “compostable” on their website.

Secondly, is the aluminum layer itself truly compostable? Or the laquer (plastic) coatings? Or is it the paper that is compostable and the remants left behind, at best, don’t impact the compost? Generally, aluminum and laquers are not considered compostable or biodegradable. Generally, composters request you do not put any kind of metal in your compost. Aluminum, even a very thin layer, is still metal.

It is misleading and greenwashing to claim compostability before they have the full data to know whether or not a. the foils/laquer can even break down under home compostable conditions (not industrially recyclable ones) and b. whether or not the soil they break down into is worm-safe (generally the requirement for home compostable certifications and ISO certifications). A lot of things are compostable in a lab, and are compostable under certain situations. But as we’ve seen recently, industrially compostable does not guarantee it will be composted, nor turn into usable soil. Home compostable requirements are extremely different from industrially compostable ones.

#2 Are Our Foils Biodegradable?

This one’s mostly accurate (it is directly copied from Google Definitions) just lacking a lot of detail. Biodegradability is actually extremely complicated and unregulated in the industry. And in fact, according to the European Environmental Agency, both biodegradable and compostable materials must be broken down “within a defined period of time” (unlike “degradable).

Biodegradable and compostable materials can be broken down by microorganisms into water, carbon dioxide, mineral salts and new biomass within a defined period of time. Whether a biodegradable or compostable plastic item biodegrades and how quickly that happens, strongly depends on the conditions it is exposed to during disposal. These include temperature, duration, the presence of microorganisms, nutrients, oxygen and moisture (De Wilde et al., 2013; van den Oever et al., 2017).

Check out more information from the European Environmental Agency.

So, again, kind of a flop for specifics and transparency. Really conveys no meaningful information about its alleged biodegradability.

#2 Is packaging using our foil repulpable?

The 80% is important information, and while I’d love to see the study that I haven’t received, this kind of specific and detailed information is important to convey when discussing the foil’s viability in any context. In the original message to me this is what should have been transparently disclosed - that there is, even in their commissioned testing, a limit to where the foil starts to impact recyclability. I’d also like to know how it impacts repulpability in more detail; Why 80% What happens at 50%? What was their threshold for impacted repulpability? What methods did they use? Are these methods standard for most recyclers? These are questions we can’t answer because their transparency is basically an opaque wall.

Also, in case you’re wondering, here’s a very simple visual breakdown of the material compositions of of the foil they use, as according to the numbers given in the above message from the representative to me.

Overall Take

I would honestly rank FoilCo’s sustainability page a D grade for transparency. It is a bit demeaning to read with the dictionary definitions as answers, is relatively uninformative, and a bit misleading in places at worst. Their “#NotAnotherEnvironmentalPolicy” PDF is a bit better, but honestly mostly repeats the sustainability page with not much more detail for the important aspects. It’s mostly a hype-document for some vague claims for what the company will do in the future. I didn’t find anything interesting to talk about from it, but if you’re curious you can check it out for yourself. Perhaps they might have been better off writing a more standard Environmental Policy instead of trying to be a bit rebellious. In my opinion, radical transparency is the rebellion. Anything else fits status quo.

I would like to say, it’s important to not blame marketing or company representatives when they talk about the companies they work for: they likely don’t know any better either, and believe what they’ve been told to market. I’ve been talked down to by a lot of reps that weren’t very familiar with the actual environmental reports out there, and that’s fine. That’s not their job. It’s just also important to be able to evaluate where these representatives are coming from: it’s their job to market the company, not to be scientifically accurate. Sometimes those things can align, but definitely always double check claims from marketing representatives before making claims in your professional careers.

So, for now, until more peer-reviewed information comes out, I’ll be avoiding foil use. Things are changing all the time, but right now, we don’t feel it’s a safe assumption to believe all or most recyclers can effectively dissolve the glues and lacquers required to adhere the foil to the paper in the de-inking process.

If a foil company representative, or even better, a recycler is reading this and has more information that gleans more insight into either the recyclability or non-recyclability of foils, we’d love to know, and highly encourage you to email us at hello@littlefoxdesign.com.

This issue was written by both myself and my partner, Sastun who kindly wrote up the lab report and breakdown section!

This Substack is reader supported! If you enjoyed, consider sharing with a friend who you think might enjoy it, or subscribing yourself for free!